More than 4 million vehicles are pretreated annually with Henkel’s next generation metal pretreatment process, which today received the second-place award in the sustainability category of the 2021 Altair Enlighten Awards. The award honors the greatest sustainability and lightweighting advancements in the automotive industry. Henkel’s Altair Enlighten Award recognizes the use of the PALLUMINA™ metal pretreatment process on the 2021 Toyota Tacoma and Tundra.

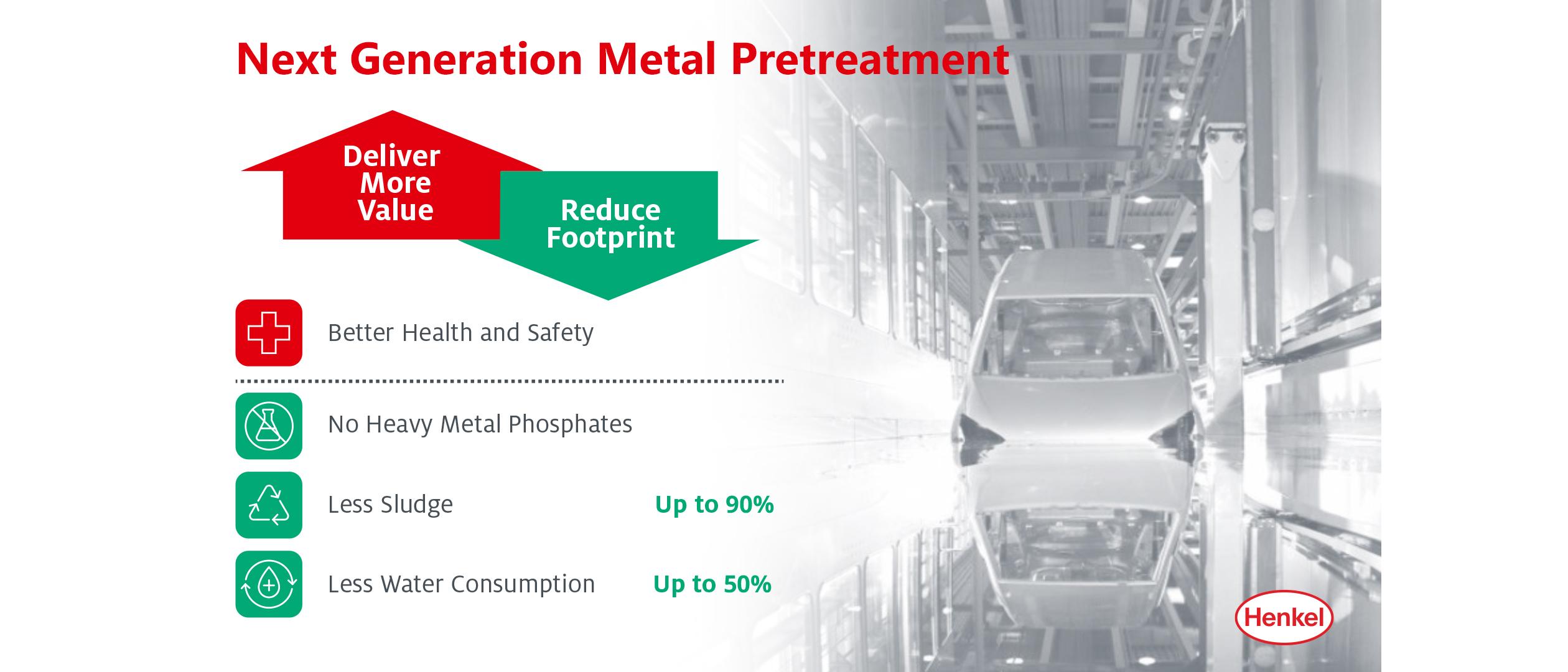

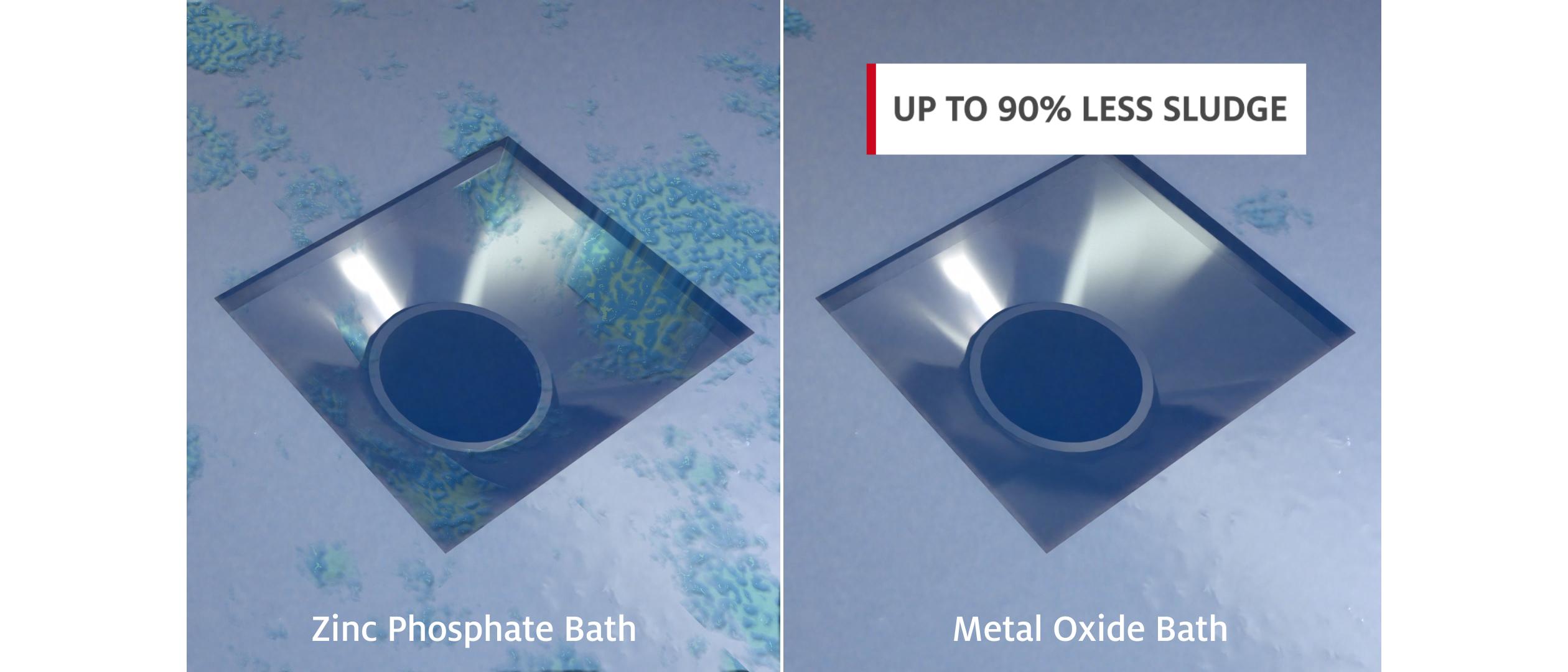

Metal pretreatment is an essential part of vehicle production, as it enables paint adhesion to the vehicle body, while preventing corrosion. Henkel’s next generation metal pretreatment process, also referred to by Henkel as the Bonderite® Thin Film Process and PALLUMINA, reduces the manufacturing steps of a conventional metal pretreatment process from seven to four. Key environmental advancements include the elimination of heavy metal phosphates, such as zinc phosphate, nickel phosphate and manganese phosphate, up to a 90 percent reduction in sludge generation, up to a 40 percent reduction in energy and up to a 50 percent reduction in water usage.

“Sustainability advancements are absolutely crucial to both Henkel and our customers,” said Mike Quail, Senior Corporate Vice President, Global Automotive OEMs, Henkel. “Ambitious targets to cut carbon footprint, reduce waste and use more renewable energy are in place throughout the automotive industry. Henkel’s next generation metal pretreatment process is just one example of how we’re helping our customers reach those goals.”

Henkel’s next generation metal pretreatment process is effective across all major metals and can process up to 100 percent aluminum, further enabling the use of this lightweight metal. Use of aluminum is expected to double from approximately 13 percent on passenger cars and trucks today to 26 percent by 2040, according to the Center for Automotive Research. Aluminum plays an essential role in improving fuel economy standards of internal combustion engine vehicles and off-setting added weight of Battery Electric Vehicles.

Additional information about the Altair Enlighten Awards is available here.

PALLUMINA™ is a trademark of Nihon Parkerizing. Henkel has a technical alliance with Nihon Parkerizing and is supplying Toyota with PALLUMINA as their OEM product.