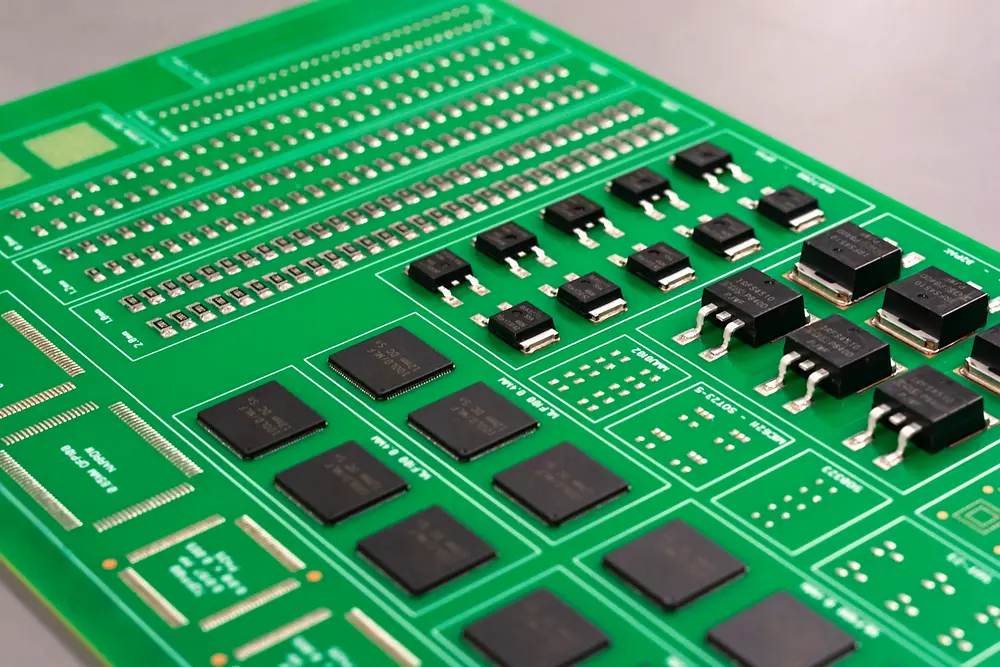

As with other automotive electronic components, the design of ADAS control units is challenged by weight and footprint – miniaturization of components becomes increasingly important. Non-lead packages (without leads or pins sticking out of the side of the package) contribute to optimizing the component footprint on a printed circuit board (PCB). In some cases, it can be optimized from 40 to 80% by changing from standard packages to non-lead packages, when multiplied by the number of components on the control unit the real-state becomes significant.

Automotive solder joints should be designed to be as reliable as possible, because they play a central role in keeping the driver, passengers and pedestrians safe. Each solder joint must provide reliable electrical conductivity and mechanical fixation. Some designers raise concerns about the reliability of the solder joints as non-lead packages expand under thermal stress and shear strain forces may originate micro cracks at the interconnection. In many cases, conventional tin-silver-copper (also known as SAC) lead-free solder paste materials are not able to meet the requirements of applications in ADAS and other critical automotive components. That is why Henkel joined together with partners to create the innovative 90iSC alloy. The creep resistance and tensile strength of the 90iSC alloy surpasses targets of SAC and SnPb (tin-lead) alloys at all measured strain rates and temperatures, maintaining a stable grain structure and ensuring assemblies are more robust preventing electrical failures. With its durability and adaptability, 90iSC has become the leading high-reliability, lead-free and RoHS-compliant solder alloy.

Henkel offers a complete range of Loctite solder paste solutions capable of exceeding the challenges of harsh environments for safety-critical electronic applications, and compliant with the automotive engineering test MS184-01 for high stress components maintaining a stable interconnection with more than 75% original solder joint strength after thermal cycling.

For more information about Henkel’s 90iSC alloy please visit www.henkel-adhesives.com/electronics.