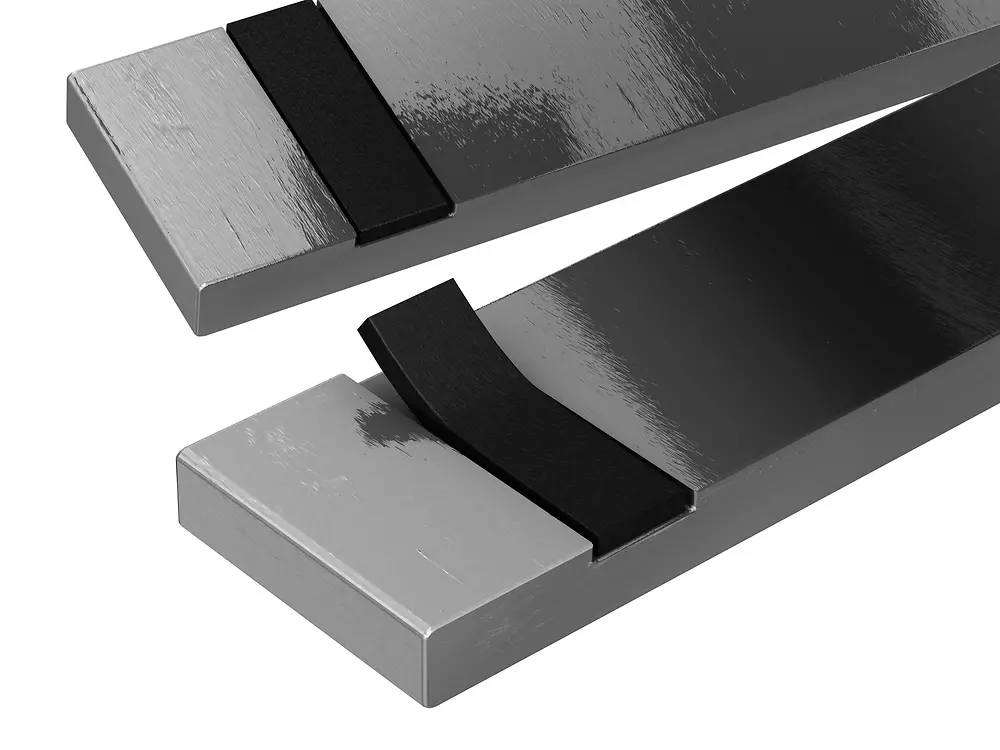

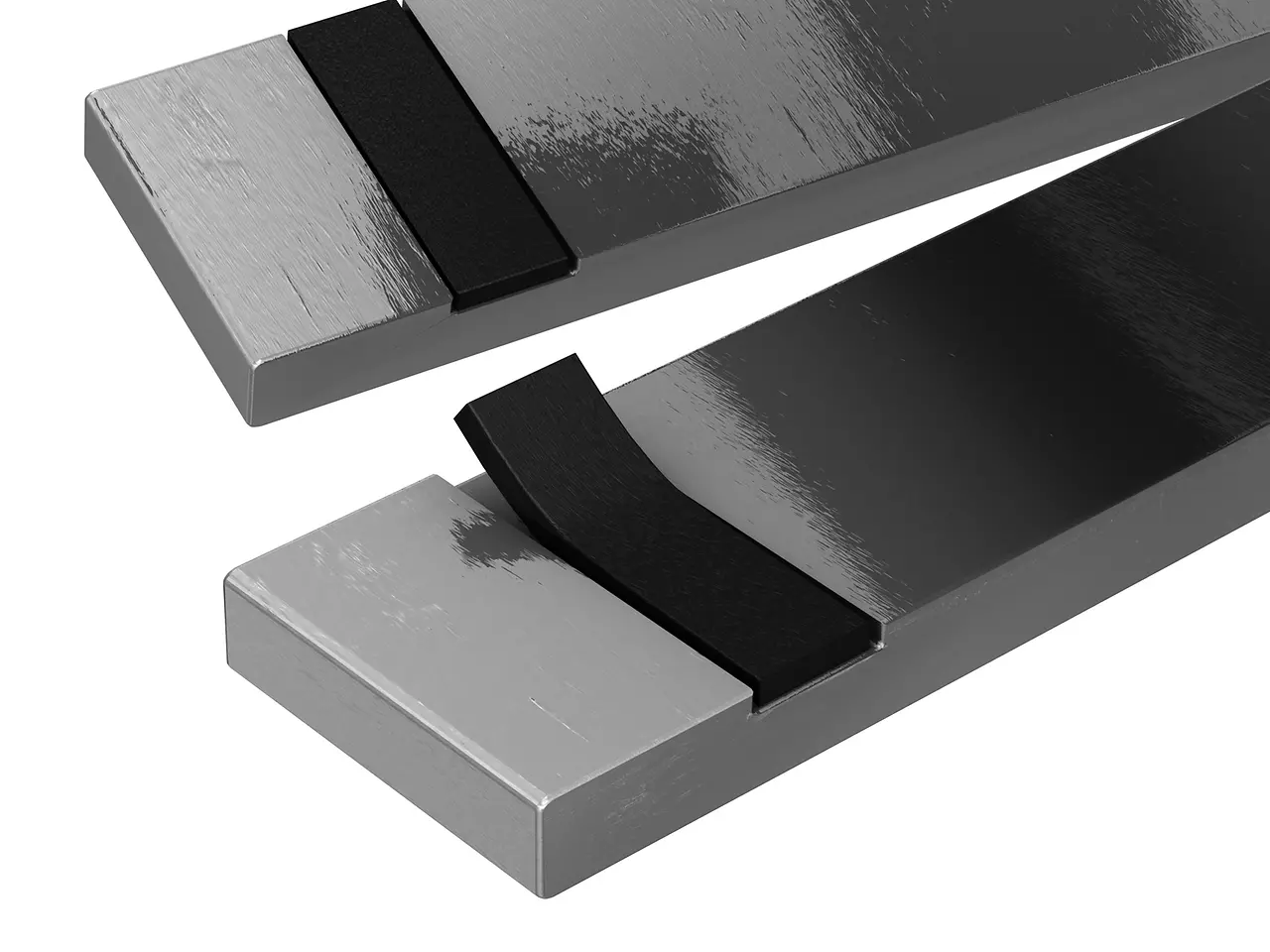

Loctite EA 9536 offers unique properties compared to existing solutions on the market. The epoxy-based adhesive film can be produced in various sizes and shapes customized to the specific application. Thanks to its low-tack characteristic the product is easy to apply. In addition, Loctite EA 9536 can absorb oil and dirt and thus eliminates the need to clean the surface. After application, the special epoxy resins create a strong and elastic bond that holds magnets securely in position.

Відкрийте для себе бренди та технології наших бізнес-підрозділів «Henkel Клейові технології» Henkel Adhesive Technologies і «Henkel Споживчі бренди» Henkel Consumer Brands.